As we approach 2026, the data is undeniable: accessories—specifically heavy hardware and jewelry—have evolved into the highest-margin category for streetwear brands. For independent designers, the barrier to entry isn’t creativity. It’s execution. While sketching a Cuban link chain or a pendant is accessible, navigating the complex world of manufacturing often stalls promising brands before they launch. Historically, the industry was gated by prohibitive “Minimum Order Quantities” (MOQs) and months-long lead times, but a shift in the supply chain is rewriting these rules.

As we approach 2026, the data is undeniable: accessories—specifically heavy hardware and jewelry—have evolved into the highest-margin category for streetwear brands. For independent designers, the barrier to entry isn’t creativity. It’s execution. While sketching a Cuban link chain or a pendant is accessible, navigating the complex world of manufacturing often stalls promising brands before they launch. Historically, the industry was gated by prohibitive “Minimum Order Quantities” (MOQs) and months-long lead times, but a shift in the supply chain is rewriting these rules.

The “Agile Manufacturing” Revolution

Old-school manufacturing required volume to secure quality; today, agile production models prioritize speed and flexibility for high-frequency drops.

For decades, the standard gatekeeper for entry into jewelry production was the “500-piece minimum.” This model forced startups to tie up capital in inventory that might not sell, effectively killing cash flow. However, the modern streetwear market operates on scarcity and speed, rendering the bulk-order model obsolete.

Speed and flexibility are now the most valuable assets for any fashion startup. Waiting months for a sample is a death sentence in the trend-driven streetwear market. This is why smart brands are shifting towards manufacturers that offer “agile production” services. Leading industry partners like Azonejewelry have specifically adapted to this need, offering rapid 7-day sampling and Minimum Order Quantities (MOQs) as low as 50 pieces. This allows designers to test bold concepts—like chunky cuban chains or custom pendants—without the financial risk of overstocking.

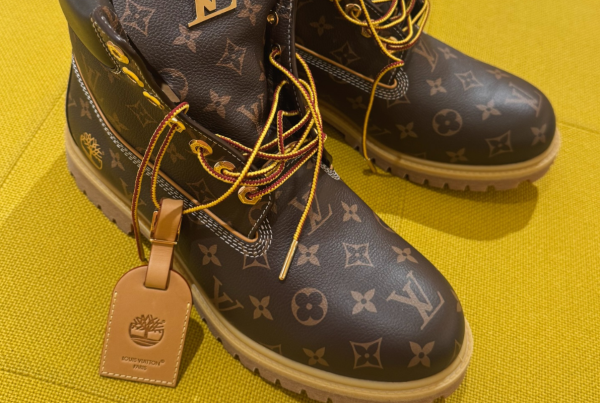

Customization is King: Beyond the “Blanks”

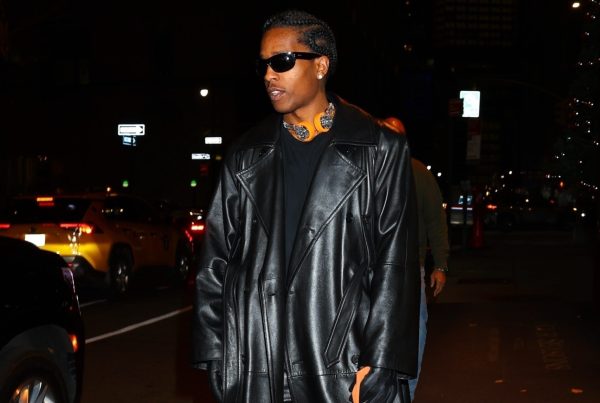

To compete with heritage luxury houses, independent brands must leverage industrial materials like Stainless Steel and advanced 3D modeling.

While sterling silver remains a classic, the streetwear sector has pivoted aggressively toward 316L Stainless Steel. It offers the weight, durability, and industrial aesthetic that defines the current “brutalist” trend, without the tarnishing issues of silver.

However, material is only half the battle. The differentiation lies in the finish and the form:

- PVD Plating: Physical Vapor Deposition is essential for gold tones, offering a coating that is ten times more durable than standard gold plating.

- 3D CAD Modeling: Utilizing computer-aided design allows for complex, hollow structures that reduce weight while maintaining visual volume.

- Laser Engraving: Essential for branding clasps and links, turning a generic chain into a branded asset.

Sustainability as a Market Driver

Transparency in the supply chain is no longer a “nice-to-have” bonus feature; it is a primary purchasing driver for Gen Z consumers.

The modern consumer is hyper-aware of “greenwashing.” They demand traceability. Investing in high-quality, sustainable materials is not just an ethical choice; it’s a financial necessity. According to comprehensive market analysis by Grandviewresearch, the global jewelry market size is projected to show significant growth, driven largely by a shift towards ethically sourced materials. Brands that can prove the durability and eco-friendliness of their supply chain (such as using recycled metals or non-toxic PVD coatings) are seeing higher retention rates among younger demographics.

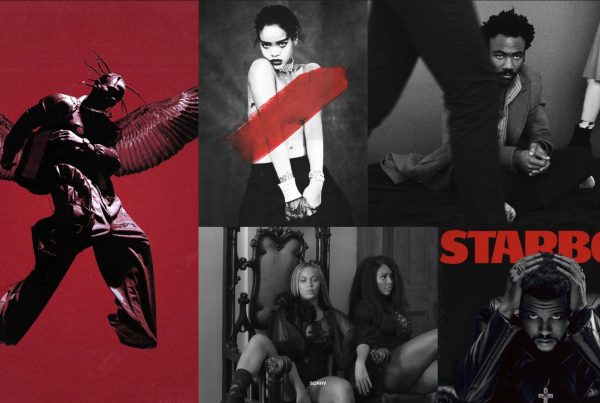

Marketing Your First Drop

Scarcity is the currency of streetwear; utilize “blind box” tactics and limited editions to drive initial momentum.

Once the supply chain is secured, the marketing strategy must match the agility of production.

- The “Drop” Model: Do not release a full collection at once. Release one hero piece every 3-4 weeks to maintain social media engagement.

- Blind Boxes: Package jewelry with mystery accessories to increase average order value (AOV).

- Visual Assets: Invest in high-contrast photography that highlights the texture and weight of the metal.

Key Takeaways

| Area | Key Takeaway | Impact/Data |

| Production | Switch to “Agile Manufacturing” | MOQ reduced 500 to 50 |

| Material | Adopt 316L Steel & PVD | 10x durability vs. plating |

| Speed | Rapid prototyping is mandatory | 7-day sampling cycle |

| Strategy | Execute scarcity “Drop” model | 1 release every 3-4 weeks |

| Growth | Utilize “Blind Box” tactics | Increases Average Order Value |

Conclusion

In 2026, the brands that win won’t necessarily be the ones with the biggest budgets, but the ones with the most responsive supply chains. By leveraging agile manufacturing, sustainable practices, and strategic drops, independent designers can finally compete on a global stage.