Technology continues to redefine the way industries evolve, and fashion is no exception. From fabric innovation to sustainability solutions, fashion is increasingly looking outside its traditional boundaries to adopt smarter ways of working. While the industry has always thrived on creativity and aesthetics, it’s now being pushed towards efficiency, function, and performance. Drawing inspiration from sectors like automotive, aerospace, and even tech startups, fashion is beginning to integrate intelligent systems, data, and engineering into clothing production and design.

Technology continues to redefine the way industries evolve, and fashion is no exception. From fabric innovation to sustainability solutions, fashion is increasingly looking outside its traditional boundaries to adopt smarter ways of working. While the industry has always thrived on creativity and aesthetics, it’s now being pushed towards efficiency, function, and performance. Drawing inspiration from sectors like automotive, aerospace, and even tech startups, fashion is beginning to integrate intelligent systems, data, and engineering into clothing production and design.

Sectors known for precision and innovation have long been applying data-driven decision-making and advanced materials. These are traits the fashion industry can emulate more consistently. Think of the way sportswear brands already collaborate with biomechanical experts to develop performance gear. Now, that same collaborative model is creeping into ready-to-wear collections. With wearable technology becoming more mainstream, fashion is increasingly exploring garments that monitor health, adapt to temperature, and even charge electronic devices—all once considered science fiction, now viable thanks to lessons from adjacent industries.

Interestingly, the gambling and entertainment sectors also demonstrate how agility and streamlined systems appeal to modern consumers. In online gambling, for example, there’s rising interest in casinos with no KYC 2025, which help eliminate lengthy verification processes in favour of speed and convenience. Fashion brands could take note—consumers are gravitating toward experiences that prioritise frictionless interaction. Whether through simplified returns, smarter fitting tools, or faster customisation, the apparel industry can benefit from understanding how other sectors refine user experience with technology.

Smart textiles offer one of the clearest opportunities for crossover learning. These are fabrics embedded with conductive fibres that can interact with devices or provide sensory feedback. The medical and military fields have utilised them for years to monitor vital signs or enable communication in remote conditions. Fashion can adopt these capabilities in stylish yet practical ways—imagine a jacket that adjusts its insulation based on external temperature, or gym wear that signals dehydration through subtle vibrations. These applications could redefine everyday apparel.

Another critical area is automation. Manufacturing sectors outside fashion have embraced robotics and machine learning to improve efficiency and reduce waste. The fashion industry, often reliant on manual labour and fragmented supply chains, has been slower to catch up. However, adopting automated cutting, sewing, and 3D knitting technologies can streamline production. The bonus? Less fabric waste and fewer human errors. It also supports localised manufacturing models, reducing reliance on far-flung factories and increasing transparency.

Artificial intelligence, meanwhile, is already changing how products are recommended to consumers, but its power can go far beyond personalisation. Predictive analytics used in finance and logistics could help fashion brands better anticipate demand, plan stock more accurately, and avoid overproduction. With sustainability high on the agenda, using AI to produce only what is needed aligns perfectly with goals to reduce waste and carbon footprint. Learning from how supermarkets or electronics retailers manage supply can offer useful models.

The aerospace industry, with its obsession over lightweight, durable materials, also offers inspiration. Ultra-light composites and heat-resistant fibres used in space travel can trickle down into consumer wear—particularly in outdoor or performance-focused clothing. These materials could lead to coats that are feather-light yet weatherproof or footwear that remains durable under extreme stress. Fashion should see this as more than novelty; it’s about combining functionality with aesthetics in ways that meet modern lifestyle demands.

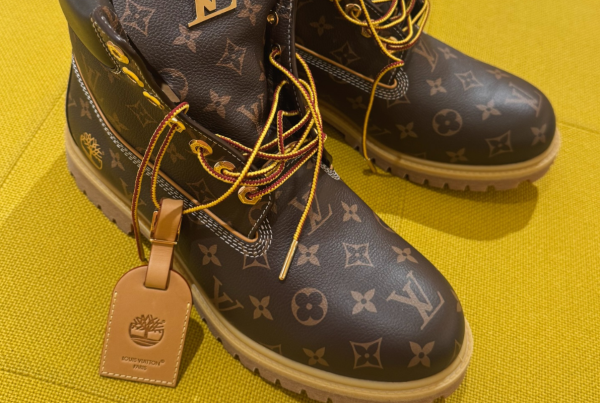

3D printing is another frontier where lessons from other sectors can be transformative. Already used extensively in healthcare for prosthetics and dental work, 3D printing allows for custom shapes and precision fits. In fashion, this means clothing and accessories made with minimal waste and maximum individuality. Footwear brands have experimented with printed soles tailored to the user’s foot shape. The next step? Entire garments printed to fit your measurements, eliminating sizing inconsistencies and return rates.

Incorporating data into design is another borrowed concept gaining momentum. The automotive industry uses real-time data to inform design tweaks and customer needs. Fashion can adopt similar feedback loops. Smart mirrors, apps, and online tracking tools can help brands understand how consumers use their products post-purchase. Are the zippers failing? Are customers layering items in unexpected ways? Feeding this insight back into design can improve product performance and customer satisfaction.

Blockchain technology, initially a breakthrough in finance, has relevance for fashion too—particularly in terms of transparency and authenticity. High-end brands are beginning to use blockchain to verify the provenance of luxury items, preventing counterfeits and building trust with customers. With increased demand for ethical production, providing a digital trail for every garment from farm to store can be a powerful selling point. This level of traceability is already being tested in food supply chains and could become a fashion standard.

By looking beyond its own borders, the fashion industry stands to benefit enormously. Other sectors have already cracked many of the challenges fashion now faces—whether it’s reducing waste, improving speed to market, or enhancing customer experience. Integrating technology doesn’t mean losing creativity; it means enabling it with better tools and insights. In a world where consumers are demanding more functionality and accountability from the clothes they wear, it’s clear that fashion’s future lies not just in style, but in smart adaptation.